Product

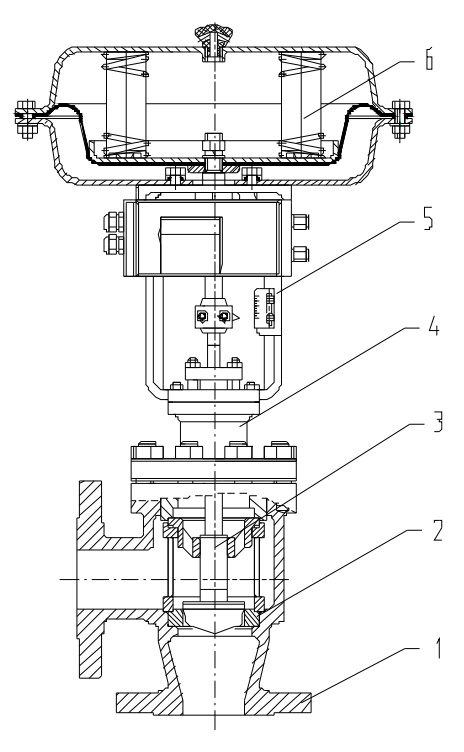

Electric/pneumatic diaphragm angle valve

Pneumatic/electric angle regulating valves adopt a modular design with strong universality and interchangeability, and have a compact structure. The conventional top-guided structure, plus the optional bottom-guided structure below the valve seat, makes it suitable for various high-stability, high-pressure difference occasions, meeting user requirements. Specifically designed for media with high viscosity, easy crystallization, containing particles, and 90° elbow connections, the angle regulating valve body has no dead angle, facilitating purging, therefore it is particularly widely used in the food industry. <br/> This series of products includes various types such as standard type, heat dissipation type, low temperature type, regulating and cut-off type, and bellows sealed type. Product nominal pressure ratings are P(MPa) 1.6, 2.5, 4.0, 6.4, 10.0 (150lb, 300lb, 600lb); valve body diameter range DN(mm) 20~400 (3/4”~16”); applicable fluid temperature -196~+560℃ in various grades; leakage standard has V class, V class, V class; flow characteristics include linear and equal percentage. A wide variety of specifications are available.

Keyword:

- Product Description

-

Pneumatic/electric angle regulating valves adopt a modular design with high universality and interchangeability, and have a compact structure. The conventional top-guided structure, plus the optional bottom-guided structure below the valve seat, makes it suitable for various high-stability, high-pressure difference occasions, meeting user requirements. Specifically designed for media with high viscosity, easy crystallization, containing particulates, and 90° elbow connections, the angle regulating valve body has no dead angle, facilitating purging, therefore it is widely used in the food industry.

This series of products includes standard, heat dissipation, low-temperature, regulating and cut-off, and bellows sealed types. Nominal pressure ratings are P(MPa) 1.6, 2.5, 4.0, 6.4, 10.0 (150lb, 300lb, 600lb); valve body diameter range DN(mm) 20~400 (3/4”~16”); applicable fluid temperature -196~+560℃ in various grades; leakage standards include V-class, V-class, V-class; flow characteristics include linear and equal percentage. A wide variety of specifications are available.

Working Principle:

Pneumatic ZXS:

The positioner receives standard current signals or computer signals, converts them into valve position setpoints, and the linear displacement of the actuator is converted into angular displacement through a connecting device and measured by a position sensor, which is fed back to the microprocessor. The microprocessor compares the actual valve position feedback value with the setpoint value. When a deviation is detected, a pulse width modulation (PWM) instruction is output to the piezoelectric valve according to the magnitude and direction of the deviation. The piezoelectric valve adjusts the air intake or exhaust volume of the diaphragm head according to the control instruction.

Electric ZDLS:

The standard current signal or computer signal is converted by A/D conversion and enters the intelligent signal acquisition and control unit of the intelligent electric actuator. The signal acquisition and control unit constantly monitors the input signal and position feedback signal. When the two signals are unbalanced, a pulse width modulation (PWM) instruction is output to the bidirectional thyristor according to the magnitude and direction of the deviation, causing it to conduct and drive the motor to rotate in the direction of reducing the deviation, thereby driving the speed reduction mechanism and changing the valve opening.

Control Mode:

The control mode uses PWM (Pulse Width Modulation) drive:

Full speed state: When the control deviation is large, a continuous signal is output:

Medium speed state: When the deviation is small, a pulse signal is output:

Slow fine-tuning: When the deviation is very small, a smaller pulse signal is output,

Maintain positioning: When the deviation is small enough to be within the valve adjustment accuracy range, no control instruction is output.

1. Valve body 2. Valve seat 3. Valve stem 4. Valve cover 5. Bracket 6. Actuator

This series of regulating valves adopts a modular design and can be used with various accessories in different combinations.

Type:

Standard type: Operating temperature -20~+200℃, leakage grade IV

Heat dissipation type: The valve cover is equipped with a heat sink, which can be used in occasions with a medium temperature of -60~+450℃

Regulating and cut-off type: The soft sealing structure valve core reaches the V-class leakage standard;

Bellows sealed type: Completely seals the up and down movement of the valve stem, preventing fluid leakage

Low temperature type: Using a long neck valve cover and bellows seal, it can be used at -196℃

Jacket insulation type: Used in occasions where the fluid is easily crystallized and solidified after cooling, causing blockage.

The valve core and valve seat are welded with Stellite alloy, suitable for high temperature, cryogenic and other harsh working conditions

Keyword:

Benefiting from all the advantages of the 1ZQ actuator, the IZQ+VE features a linear output transmission system, with adjustable thrust output up to 100KN

IZQ-Multi-turn Actuator Model 18-40

Advanced intelligent non-invasive electric valve actuators, offering multi-turn, partial-turn, and linear stroke options.

Part of the IZQ+BW rotary actuator

The IZQ+BW actuator is based on the IZQ multi-turn actuator with a secondary deceleration stage, enabling 90° opening and closing of large-diameter, high-torque butterfly valves, ball valves, etc., with a torque range of 1000Nm~63000Nm

I want to consult

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.