Product

O-type cut-off ball valve

The "O" type cut-off ball valve is a two-piece ball valve structure. The valve body consists of two parts, the main and the auxiliary. The ball core adopts a full-bore design, with a large rated flow coefficient and low flow resistance. The soft-sealed ball core surface is hardened using a special process, making it smooth and wear-resistant. The valve seat sealing material is carbon fiber reinforced polytetrafluoroethylene; the hard-sealed ball core surface is treated with tungsten carbide spraying, which has extremely strong wear resistance, and the valve seat sealing material is stainless steel welded Stellite alloy, with a long service life. The actuator uses a high-performance double-piston gear-rack structure, with high transmission efficiency and compact structure, or an electronic electric actuator. The nominal diameter range of this series of products is DN15~300mm (1/2”~12”), and the nominal pressure rating is PN1.6、4.0、6.3 MPa (150lb、300lb).

Keyword:

- Product Description

-

The "0" type shut-off ball valve is a two-piece ball valve structure. The valve body consists of two parts, the main and the auxiliary. The ball core uses a full-bore design, with a large rated flow coefficient and low flow resistance. The soft-sealed ball core surface is hardened using a special process, making it smooth and wear-resistant. The valve seat sealing material is carbon fiber reinforced polytetrafluoroethylene; the hard-sealed ball core surface is treated with tungsten carbide spraying, which has extremely strong wear resistance, and the valve seat sealing material is stainless steel brazed titanium alloy, with a long service life. The actuator uses a high-performance double-piston gear-rack structure, with high transmission efficiency and compact structure, or an electronic electric actuator. The nominal diameter range of this series of products is DN15~300mm (1/2”~12”), and the nominal pressure rating is PN1.6、4.0、6.3 MPa(150lb、300lb).

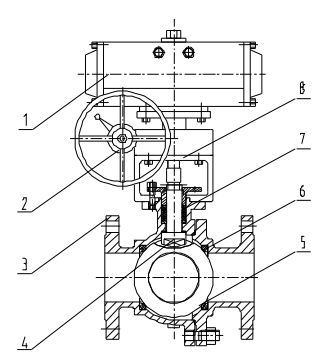

1. Actuator 2. Handwheel 3. Valve Body 4. Stem 5. Ball Core 6. Valve Seat 7. Packing 8. Bracket

Features:

1. Valve seat limit structure (stable torque): The valve seat sealing ring is reasonably pre-tightened and limited, greatly reducing the operating torque; a spring is installed at the bottom of the valve seat to maintain stable torque;

2. Stem anti-ejection design (safe and reliable): Bottom-mounted stem, preventing the stem from being ejected due to excessive medium pressure, completely eliminating safety hazards:

3. Unique fire-resistant design (can maintain sealing after fire): The soft-sealed valve seat adopts a combination valve seat consisting of a stainless steel seat with a sealing surface wrapping a polytetrafluoroethylene sealing ring. There is a small gap between the stainless steel seat sealing surface and the ball. When the polytetrafluoroethylene sealing ring is burned, the floating ball is pressed against the stainless steel seat under the action of the medium pressure, and at the same time, relying on the action of the spring at the bottom of the valve seat, the stainless steel seat is pushed towards the ball core, forming a seal between the sealing surfaces of the ball and the stainless steel seat:

4. Anti-static device (can lead out static electricity): A simple and easy-to-install anti-static device ensures that the ball, stem, and valve body are always connected as one, and the static electricity generated by friction between the sealing surfaces due to switching is led out:

5. Standard actuator: Pneumatic and electric are interchangeable.

Keyword:

Benefiting from all the advantages of the 1ZQ actuator, the IZQ+VE features a linear output transmission system, with adjustable thrust output up to 100KN

IZQ-Multi-turn Actuator Model 18-40

Advanced intelligent non-invasive electric valve actuators, offering multi-turn, partial-turn, and linear stroke options.

Part of the IZQ+BW rotary actuator

The IZQ+BW actuator is based on the IZQ multi-turn actuator with a secondary deceleration stage, enabling 90° opening and closing of large-diameter, high-torque butterfly valves, ball valves, etc., with a torque range of 1000Nm~63000Nm

I want to consult

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.