Product

O-ring PTFE-lined ball valve

The O-ring lined PTFE ball valve is a full-bore floating (two-piece) and full-bore fixed ball (three-piece) ball valve structure. The valve body and ball are lined with fluoroplastic, mainly used for cutting off or connecting corrosive media in pipelines, and can also be used for fluid regulation and control. The actuator uses a high-performance double-piston rack and pinion structure, with high transmission efficiency and compact structure, or an electronic electric actuator.

Keyword:

- Product Description

-

The "O" type fluoroplastic lined ball valve is a full bore floating (two-piece) and full bore fixed ball (three-piece) ball valve structure. The valve body wall and ball core are lined with fluoroplastic, mainly used for cutting off or connecting corrosive media in pipelines, and can also be used for fluid regulation and control. The actuator uses a high-performance double-piston gear rack structure, with high transmission efficiency and compact structure, or an electronic electric actuator. The nominal diameter range of this series of products is DN15~250mm (1/2”~10”), and the nominal pressure level is PN1.0, 1.6Mpa (150lb).

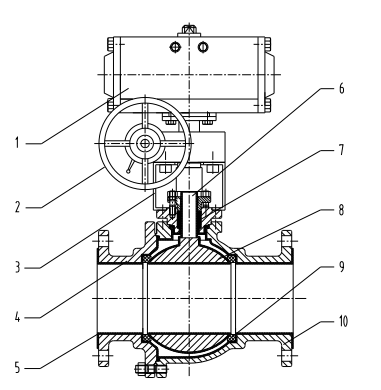

1. Actuator 2. Handwheel 3. Bracket 4. Valve body 5. Ball core 6. Valve cover 7. Lining layer 8. Packing 9. Valve seat

Features:

1. Low fluid resistance, the inner wall of the lined ball valve is smooth, and the flow path is unobstructed, making it the valve with the lowest fluid resistance among all valve types:

2. Quick and convenient switching, only needs to rotate the ball 90° to complete the opening and closing action:

3. Using a special molding process, the lining material is lined on the inner wall of the valve shell, which can withstand the corrosion of strong acids and alkalis. The lined ball surface and PTFE valve seat combination ensures good sealing and zero leakage;

4. The ball and stem are integrated in design, eliminating the turning angle difference and preventing the possibility of pressure-bearing parts being ejected due to pressure changes, ensuring safety and reliability;

5. Valve seat limit structure (stable torque): The metal limit structure at the main and auxiliary valve body connection and the connection between the valve body and the packing gland ensures reasonable pre-tightening and limiting of the valve seat sealing ring, greatly reducing the operating torque:

6. Standard actuator: Pneumatic and electric are interchangeable.

Keyword:

Benefiting from all the advantages of the 1ZQ actuator, the IZQ+VE features a linear output transmission system, with adjustable thrust output up to 100KN

IZQ-Multi-turn Actuator Model 18-40

Advanced intelligent non-invasive electric valve actuators, offering multi-turn, partial-turn, and linear stroke options.

Part of the IZQ+BW rotary actuator

The IZQ+BW actuator is based on the IZQ multi-turn actuator with a secondary deceleration stage, enabling 90° opening and closing of large-diameter, high-torque butterfly valves, ball valves, etc., with a torque range of 1000Nm~63000Nm

I want to consult

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.