Product

Lined butterfly valves

Rubber-lined and fluoroplastic-lined butterfly valves are designed and developed for slurry pipelines in large coal-fired power plant desulfurization and denitrification systems. They are also suitable for transporting liquids and gases (including steam) in various industrial pipelines, especially those with corrosive media such as sulfuric acid, phosphoric acid, hydrofluoric acid, chlorine, strong alkalis, aqua regia, etc. This product features excellent shut-off performance, strong corrosion resistance, and a long service life.

Keyword:

- Product Description

-

Rubber-lined and fluoroplastic-lined butterfly valves are designed and developed for slurry pipelines used in large coal-fired power plant desulfurization and denitrification systems. They are also suitable for transporting liquids and gases (including steam) in various industrial pipelines, especially those with corrosive media such as sulfuric acid, phosphoric acid, hydrofluoric acid, chlorine, strong alkalis, aqua regia, etc. This product features excellent shut-off performance, strong corrosion resistance, and a long service life.

Features:

The rubber-lined butterfly valve's body is lined with EPDM (ethylene propylene diene monomer rubber), offering excellent corrosion resistance and erosion resistance, and a long lifespan; the valve plate material uses duplex stainless steel 2205, 1.4529, etc., which has extremely strong chloride ion corrosion resistance (can withstand 40000ppm chloride ions), excellent comprehensive mechanical properties, and very high surface hardness. It is especially suitable for slurry media with corrosion and particles that are easily eroded, such as fly ash.

Austenitic stainless steel can also be used depending on the operating conditions; the valve plate with a mirror-like finish and the sealing pair of EPDM (ethylene propylene diene monomer rubber) with good chloride ion resistance, strong toughness, and elasticity achieve complete sealing, and the airtightness test achieves zero leakage; low flow resistance, large rated flow coefficient; this butterfly valve product uses a double-flanged connection.

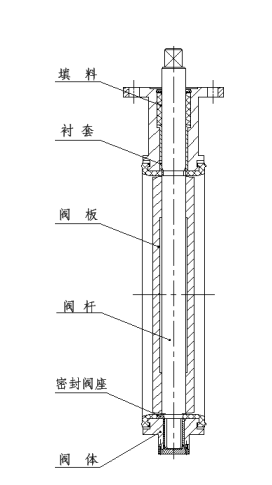

The fluoroplastic-lined butterfly valve uses a polytetrafluoroethylene (PTFE)-lined butterfly plate with a spherical sealing surface, and a silicone rubber gasket at the valve seat base adjusts the valve's sealing performance; this valve is easy to operate, has tight sealing performance, and an ultra-long service life; it can be used for quick shut-off or flow regulation. The valve body is split, and the sealing at both ends of the valve stem is controlled by fluororubber on the rotating surface between the butterfly plate and the valve seat: thus achieving a compact structure, beautiful appearance, reasonable process, and reliable performance.

The closed connection ensures that the valve stem does not contact the medium in the flow path. The split valve body connection not only facilitates the replacement of the valve stem in the pipeline but also allows for convenient and quick adjustment of the sealing performance. Low flow resistance, large rated flow coefficient; this butterfly valve product uses a double-flanged connection.

Keyword:

Benefiting from all the advantages of the 1ZQ actuator, the IZQ+VE features a linear output transmission system, with adjustable thrust output up to 100KN

IZQ-Multi-turn Actuator Model 18-40

Advanced intelligent non-invasive electric valve actuators, offering multi-turn, partial-turn, and linear stroke options.

Part of the IZQ+BW rotary actuator

The IZQ+BW actuator is based on the IZQ multi-turn actuator with a secondary deceleration stage, enabling 90° opening and closing of large-diameter, high-torque butterfly valves, ball valves, etc., with a torque range of 1000Nm~63000Nm

I want to consult

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.