Product

Self-acting pressure regulating valve

Self-acting pressure regulating valves are actuators that automatically regulate using the energy of the controlled medium itself without any external energy. The biggest advantage of this product is that it can be used in places without electricity or gas, while saving energy. The pressure setting period can be adjusted freely within a certain range. According to the needs of various process occasions, self-acting pressure regulating valves have three types of internal parts: single-seat self-acting pressure regulating valves, sleeve self-acting pressure regulating valves, and double-seat self-acting pressure regulating valves. Users can choose according to the working conditions (pressure difference, temperature, medium state) and leakage requirements. According to the needs of various process occasions, self-acting pressure regulating valves have three types of valve cover types: ordinary (general occasions), long neck (large pressure regulation range), and heat dissipation (temperature 350~550℃).

Keyword:

- Product Description

-

Self-acting pressure regulating valves are actuators that do not require any external energy source and automatically regulate using the energy of the controlled medium itself. The biggest advantage of this product is that it can be used in places without electricity or air, while saving energy. The pressure setting range is freely adjustable within a certain range. According to the needs of various process occasions, self-acting pressure regulating valves have three types of internal components: single-seat self-acting pressure regulating valves, sleeve self-acting pressure regulating valves, and double-seat self-acting pressure regulating valves. Users can choose according to the operating conditions (pressure difference, temperature, medium state) and leakage requirements.

According to the needs of various process occasions, self-acting pressure regulating valves have three types of valve cover styles: ordinary (general occasions), long neck (large pressure regulation range), and heat dissipation (temperature 350~550℃). According to the needs of various process occasions, self-acting pressure regulating valves have three types of actuator styles: diaphragm (ordinary diaphragm and reinforced diaphragm), piston, and metal diaphragm (0Cr18Ni9). Self-acting pressure regulating valves adopt a quick-opening flow characteristic, with sensitive action and high adjustment accuracy (error ≤10%); the valve occupies a small space (compared to a weight-type pressure reducing valve), is easy to adjust, and is therefore widely used in various equipment in petroleum, chemical industry, power, metallurgy, food, light textile, machinery manufacturing, and civil construction for pressure reduction and stabilization of gas, liquid, and steam (used for post-valve regulation) or pressure relief and stabilization (used for pre-valve regulation).

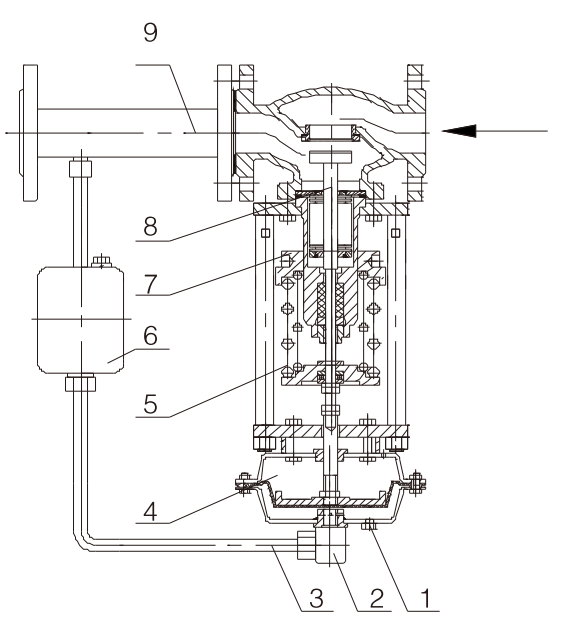

Single-seat self-acting pressure regulating valve (controlling the valve outlet) 1. Discharge plug 2. Inlet plug 3. Pressure tapping pipe 4. Actuator 5. Spring 6. Condenser 7. Adjusting disc 8. Valve core components 9. Post-valve pipe

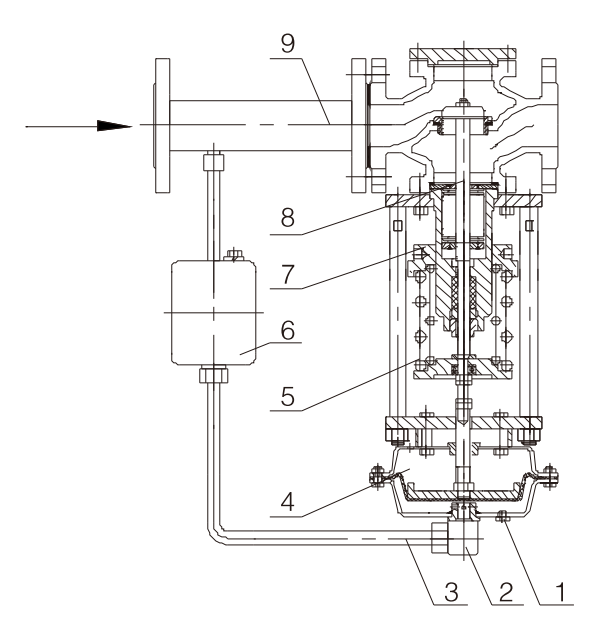

Single-seat self-acting pressure regulating valve (controlling the valve inlet) 1. Discharge plug 2. Inlet plug 3. Pressure tapping pipe 4. Actuator 5. Spring 6. Condenser 7. Adjusting disc 8. Valve core components 9. Pre-valve pipe

Structure and Principle:

The self-acting pressure regulating valve consists of a detection and execution mechanism, valve body, pressure tapping pipe, and pre-valve (post-valve) pipe.

Figure 1. Pressure regulating valve used to control post-valve pressure; the valve action is pressure-closing type. Its working principle is as follows:

The medium flows into the valve body in the direction of the arrow, and is output after throttling through the valve seat and valve core. Another path, through the pressure tapping pipe (a condenser is added when the medium is steam), is introduced into the actuator and acts on the diaphragm, causing the valve core to move accordingly, achieving pressure reduction and stabilization. If the post-valve pressure increases, the force acting on the diaphragm increases, compressing the spring and driving the valve core to reduce the valve opening until the post-valve pressure drops to the set value. Similarly, if the post-valve pressure decreases, the force acting on the diaphragm decreases, and due to the counteracting force of the spring, the valve core is driven to increase the valve opening until the post-valve pressure rises to the set value.

Figure 2. Pressure regulating valve used to control pre-valve pressure; the valve action is pressure-opening type. Its working principle is as follows:

The medium flows into the valve body in the direction of the arrow, and is output after throttling through the valve seat and valve core. Another path, through the pressure tapping pipe (a condenser is added when the medium is steam), is introduced into the actuator and acts on the diaphragm, causing the valve core to move accordingly, achieving pressure relief and stabilization. If the pre-valve pressure increases, the force acting on the diaphragm increases, compressing the spring and driving the valve core to increase the valve opening until the pre-valve pressure drops to the set value. Similarly, if the pre-valve pressure decreases, the force acting on the diaphragm decreases, and due to the counteracting force of the spring, the valve core is driven to decrease the valve opening until the pre-valve pressure rises to the set value. If the pre-valve pressure is less than the set value, the valve remains closed.

Keyword:

Benefiting from all the advantages of the 1ZQ actuator, the IZQ+VE features a linear output transmission system, with adjustable thrust output up to 100KN

IZQ-Multi-turn Actuator Model 18-40

Advanced intelligent non-invasive electric valve actuators, offering multi-turn, partial-turn, and linear stroke options.

Part of the IZQ+BW rotary actuator

The IZQ+BW actuator is based on the IZQ multi-turn actuator with a secondary deceleration stage, enabling 90° opening and closing of large-diameter, high-torque butterfly valves, ball valves, etc., with a torque range of 1000Nm~63000Nm

I want to consult

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.