Product

IZQ-Multi-turn Actuator Model 18-40

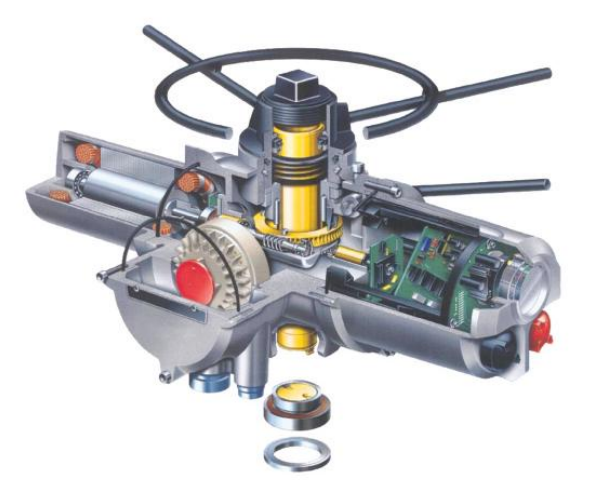

Advanced intelligent non-invasive electric valve actuators, offering multi-turn, partial-turn, and linear stroke options.

Keyword:

- Product Description

-

Advanced intelligent non-invasive electric valve actuators, offering multi-turn, partial-turn, and linear stroke options.

1. Robust structure, double sealing, effectively waterproof and dustproof (IP67/IP68-1, 2m, 48 hours) during on-site wiring.

2. Three-phase, single-phase, and DC power actuators.

3. Built-in data logger as a standard function.

4. Compatible with IrDA™ standard, allowing local and remote analysis of the actuator via insightpc software.

5. Simple, easy-to-control and indicate functions.

6. Multilingual text display showing status and settings.

7. Simple torque and position control, enhanced reliability.

8. Comprehensive control and indication flexibility.

9. Waterproof or explosion-proof specifications are available.

10. Direct torque output range 35Nm (25lbfft)~1200Nm (860 lbf ft).

Convenient Debugging:

The IZQ can be easily, safely, and quickly adjusted non-invasively using an infrared setting tool. Using the "plug-and-play" IZQ setting tool professional version, you can access and adjust actuator settings such as torque values, limit switches, control, and display functions. The unique intrinsically safe setting tool allows for non-invasive setting of the actuator in any environment, regardless of whether a power supply is available.

Simple Troubleshooting:

A large digital position indicator allows for remote real-time display of valve position. In addition, an easy-to-read, backlit display provides valve operating status, control and actuator status, and fault information. This allows users to easily understand the current operating status of the actuator. Using the Ql setting tool professional version, you can access the torque profile and actuator configuration of the relative position during debugging, adjustment, or local valve monitoring. The built-in data logger records operation, alarms, and valve torque profile data, providing valuable information on operating status and operating conditions.

IZQ-Actuator Display Features:

Actuator Display

The IZQ includes an LCD dot matrix display specifically designed for actuator display. The actuator operates normally under normal operating temperature conditions, and the large screen with backlight allows users to clearly see the valve position indication information under various lighting conditions.

The display shows in real time the command information from the central control room, the valve position, the operating status of the actuator, and the torque and alarm messages during the operation. Using the setting tool, the display can be changed from position mode to setting mode, making it easy for users to view, adjust, and change the actuator parameter settings.

The display unit also provides six LED indicators to indicate forward rotation, reverse rotation, ESD, thermal protection, phase loss, and over-torque status, respectively.

Both the display and the control cover can be rotated in 90° increments to meet various valve installation directions and positions.

Settings

Setting, adjustment, and viewing using the intrinsically safe IZQ dedicated remote control included with the device allows users to easily access the actuator configuration via the LCD display.

Help Screen

Multiple help screens can be called up using the IZQ dedicated remote control tool, allowing for real-time, grouped analysis of control signal status, valve and actuator status, and indication status.

Valve Torque Indication

The output torque limit value of the actuator can be set via the dedicated remote control buttons. The travel level of the torque switch can be checked and adjusted according to the actual valve operating torque requirements, making the setting more precise and more in line with actual requirements, thereby reducing the possibility of future failures. Problems such as valve stem packing, bottom plate, and lifting force can be immediately detected and checked and evaluated on site.

In remote control mode, operation depends on two independent signals. Taking the valve closing command as an example, both a remote valve closing input signal and a valve closing interlock input signal are provided. The actuator will operate and close the valve. If only one signal is provided or one signal is lost, the actuator will hold its position or stop to prevent failure. For applications requiring ESD, a dedicated ESD input can be used. This input has higher priority than local or remote control signals, so when this signal is applied, any current or applied control signals will be ignored.

Asset Management -- Data Logging

The dedicated remote control can be used to query the actuator configuration and construction information. This product also includes a data logger that can be used to capture valve, actuator, and control system status information and store this information in memory. This information includes:

Valve Torque Profile

Instantaneous and average torque at the corresponding valve opening/closing positions. The reference profile saved during the debugging phase can be compared with the torque profile during operation for valve performance analysis.

Startup Log

Startup position diagram at the corresponding valve opening/closing positions. Allows process control valve operation.

Statistics

Number of operations, number of power failures, operating time, maximum torque, last limit switch operation, battery operating time, battery voltage.

Detection Log

Control system, actuator, and indication event logs. Events of interest to the user, such as "torque stroke", can be replayed and filtered. The last 1024 events will be saved, noting the date and time of the event.

Manual Operation

A directly driven handwheel (or a gear-driven handwheel for larger models and those used with IZQ) provides reliable emergency manual operation in the event of a power failure. The manual/automatic disengager ensures safe operation even when the motor is running.

Note: Unless the manual/automatic handle is intentionally locked in the "manual" position, motor operation always takes precedence. Both directly driven and independently geared handwheels have a free "hammer blow" effect.

Non-Invasive Setting

All actuator setup and diagnostics are performed via IrDA™ communication through a sealed indicator window, eliminating the need to remove the cover and expose internal components on-site.

Local Control

The field control switch and local/stop/remote selector operate internal magnetic reed switches, eliminating the need for a sealed, weatherproof through-shaft.

Position Control

A Hall effect magnetic pulse system precisely measures and controls actuator travel without gears or switches.

Wiring Terminal Box

Even when the terminal box cover is open for on-site wiring, the separately sealed terminal box effectively maintains the seal and integrity of the electric actuator's interior.

IZQ Motor and Gearbox

The motor shaft and worm gear are independent, allowing for quick actuator motor replacement. The low-inertia, high-torque motor quickly reaches peak torque after startup, with virtually no overshoot during de-energization. A precise temperature sensor within the temperature coil, unaffected by ambient temperature, keeps the motor at optimal thermal capacity. The motor gearbox includes a free-stroke "hammer blow" device to assist in opening and closing tight valves. The worm wheel and worm gear operate in separate oil baths to accommodate extreme temperature variations.

Thrust Pressure

Cast iron, water-sealed bearing housing; simple, removable drive shaft sleeve machined to the valve stem for connection to the valve.

Design Features - Reliability:

Phase synchronizer prevents damage to the valve due to incorrect wiring.

The IZQ electric actuator's unique "phase synchronizer" automatically adjusts rotation to prevent motor direction errors and valve damage from incorrect three-phase power wiring. It ensures the IZQ's three-phase motor always has the correct phase sequence. The synchronizer detects the impending phase rotation and then energizes the appropriate contacts, ensuring the actuator moves in the correct direction.

Phase Loss Protection

The IZQ controller monitors all three phases of the power supply. If one or more phases are lost, the controller prevents operation to avoid "single-phasing" or motor burnout. The actuator will also display phase loss information and provide remote alarm status indication from configurable indicator nodes.

IZQ Overheat Protection

If the coil overheats, the temperature regulator in the motor coil directly detects the coil temperature and disconnects the actuator's control circuit.

Instantaneous Reversal Protection

When the actuator receives an instantaneous reversal command, an automatic time delay circuit prevents unnecessary wear and tear on the valve stem and gearbox from shock loads. This circuit also limits surge current via the contactor.

Motor Protection When Valve is Stuck

Actuators face their most severe test when valves are loose, operating forces reach their maximum, or valves occasionally become stuck during operation. IZQ's intelligent features systematically handle these issues, ensuring reliable valve operation while protecting both the valve and actuator.

If a valve is likely to become "stuck," a torque switch bypass can be set at 5% of the valve's correct position for wedge gate valves. This applies "extra" torque to the mispositioned valve, averaging 1.4 to 2 times the rated torque. In most cases, the extra force will cause the stuck valve to move, allowing the equipment to continue operating. After reaching the 5% position, the torque switch returns to its correct setting until the remaining travel is complete. If this extra torque is still insufficient to move the valve, the IZQ will consider the valve stuck and stop operation within seconds to prevent further damage to the valve or motor burnout.

Automatic Self-Test and Diagnostics (ASTD)

Upon power-up, the actuator automatically checks the operating circuits to ensure correct operation. Rare equipment malfunctions can be diagnosed and automatically displayed on the screen via icons, while the actuator's electric operation is disabled for on-site maintenance.

Design Features - Protection:

Protection is Key

Extensive experience with electric actuators has made our products world leaders in actuator protection. They reliably operate in environments ranging from deserts to tundra, sea level to underground, where conditions are humid, extremely hot or cold, and the air is highly UV-exposed and corrosive. We know the most important factor in actuator reliability is freedom from environmental influences—in short, the protective housing.

Double Sealing, Double Protection

The IZQ has an IP68 rating—submersible to 2 meters for 48 hours, NEMA4/4X16. Completely waterproof and dustproof, it is also "airtight." The "double seal" system ensures internal components are protected because they are isolated from the terminal box by a waterproof wiring terminal module. Protection is maintained even during on-site wiring with the terminal cover removed, thanks to the sealed wiring terminal module cover.

Non-Invasive - Lifetime Seal

No need to remove the electrical box cover during IZQ field commissioning. All settings and adjustments, including setting the IZQ's speed, are done using the provided infrared setting tool. After assembly in our controlled factory environment, air convection is eliminated, and all internal components are protected for life. Non-invasive control means no through-shaft is used through the control box.

Simple, Reliable

The IZQ combines a simplified design with expanded specifications and performance.

Valve Position Measurement

Reliable process control depends on accurate positioning at the end of the valve stroke. Hydraulic control, however, depends on accurate positioning in the middle of the valve stroke. The IZQ non-contact valve position measurement system is the simplest design in actuator control. A single-moving-part resolver converts the rotation of the output center sleeve into an electrical signal, which is then compared to limit values stored in secure, non-volatile memory.

Torque Measurement

The ability of the actuator to reliably and accurately determine the force required to operate a valve is fundamental to protecting both the valve and the actuator. The IZQ series uses proven technology verified by industrial practice to obtain accurate and repeatable torque measurements regardless of frequency, voltage, and temperature variations.

In recent years, integrating industrial control systems using network connections has become a major feature of the IZQ series of actuators. Actuators using fieldbus control systems simplify, make reliable, and facilitate the control and monitoring tasks of modern factories.

All IZQ actuators come with a range of optional components, allowing compatibility with various communication and process control bus systems. The actuators report status feedback to the overall plant control system (DCS or PLC) via various fieldbuses and receive valve control commands.

The IZQ series of actuators can be configured with Foundation Fieldbus, Profibus, Modbus, and DeviceNet buses. Coupled with our company's extensive expertise in bus systems, this ensures that the IZQ series actuators consistently provide the ideal and most effective solutions for various user control systems. Inserting the appropriate circuit board module into the actuator's electrical socket—typically done during manufacturing—simplifies operation and effectively reduces costs. Combine use of the IZQ Setup Tool Professional and network testing tools for the selected protocol to test and configure the module.

Keyword:

Benefiting from all the advantages of the 1ZQ actuator, the IZQ+VE features a linear output transmission system, with adjustable thrust output up to 100KN

IZQ-Multi-turn Actuator Model 18-40

Advanced intelligent non-invasive electric valve actuators, offering multi-turn, partial-turn, and linear stroke options.

Part of the IZQ+BW rotary actuator

The IZQ+BW actuator is based on the IZQ multi-turn actuator with a secondary deceleration stage, enabling 90° opening and closing of large-diameter, high-torque butterfly valves, ball valves, etc., with a torque range of 1000Nm~63000Nm

I want to consult

*Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.